Nā huahana

Platelet Calcined Alumina Pauka

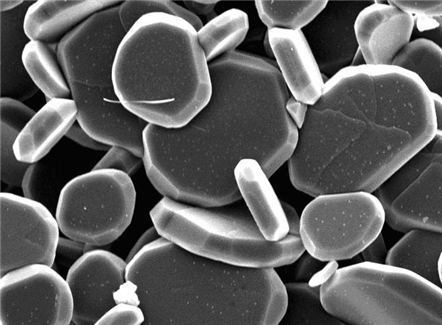

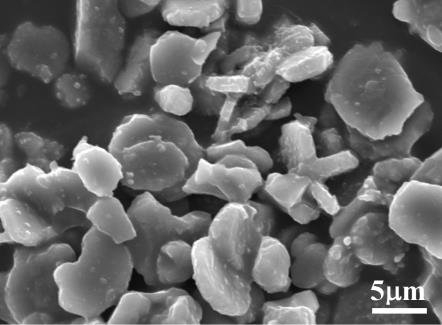

ʻO Plate Calcined Alumina polishing powder i hana ʻia me ka pauka alumina ʻoihana kiʻekiʻe e like me ka mea maka, a hana ʻia e kahi kaʻina hana kūikawā. ʻO ke ʻano aniani o ka alumina polishing pauka i hana ʻia he hexagonal pālahalaha e like me ke ʻano tabular, no laila ua kapa ʻia ʻo Platelet Alumina a i ʻole Tabular Alumina.

ʻO Platelet Alumina kahi ʻano alumina abrasive pauka kiʻekiʻe, i loaʻa i kahi aniani ʻano pāpaʻi o Al2O3 me ka maʻemaʻe o 99.0%. Loaʻa iā ia nā waiwai kūpaʻa wela maikaʻi a me ka inert kemika, ʻaʻole i ʻino ʻia e nā waikawa a i ʻole nā alkalines. E like me ka hoʻopaʻa paʻa ʻia ʻana o ka puʻupuʻu nui o Platelet Alumina, hiki iā ia ke hana i kahi ʻili liʻiliʻi maikaʻi loa, hāʻawi iā ia i ka maikaʻi kiʻekiʻe e like me ka abrasive. Me ka nui o ka hoʻohana ʻana, Platelet Alumina he pauka abrasive hiki ke hana i nā hana he nui.

ʻO ka pauka alumina tabular

ʻO ka pauka alumina tabular

Nā kikoʻī maʻamau no ka nui o ka ʻāpana

| ʻāpana | Māhele Māhele (µm) | |||

| ʻāpana nui | Nui ʻāpana | Nui ʻāpana | Nui ʻāpana | |

| 45 | <82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | <77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | <64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | <50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | <40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | <32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | <25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | <20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0.40 |

| 9 | <16.0 | 9.70±0.80 | 6.40±0.50 | 3.60±0.30 |

| 5 | <12.7 | 7.20±0.60 | 4.70±0.40 | 2.80±0.25 |

| 3 | <10.1 | 5.20±0.40 | 3.10±0.30 | 1.80±0.30 |

Kūlana Kūlana

| ʻAno huahana | Kaumaha Kūikawā | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | >3.90 | >99.0 | <0.20 | <0.10 | <1.00

|

ʻO nā pono o ka pauda alumina

1. E hoʻohālikelike me nā pauka papa ʻē aʻe, ʻo ka pauka alumina tabular nā mea hui maikaʻi loa. E like me ka helu heheʻe kiʻekiʻe, ka paʻakikī paʻakikī, ka ikaika mechanical kiʻekiʻe, ka pale ʻana i ka lole maikaʻi, ke kūpaʻa kemika, ka pale ʻana o ka oxidation a me ka pale wela etc.

2. ʻO ke ʻano o ka pepa pālahalaha e hoʻonui ai i ka friction, hoʻomaikaʻi i ka wikiwiki o ka wili ʻana a me ka maikaʻi, hiki ke hoʻemi i ka nui o nā mīkini wili, hana a me ka manawa wili.

3. ʻAʻole maʻalahi ka ʻōpala ʻana o ke ʻano o ka pepa pālahalaha, hiki ke hoʻonui i ka nui o nā huahana kūpono i ka 10% -15%. No ka laʻana, hiki i ka helu o ka wafer silicon semiconductor kūpono ke hoʻokō i 96% a i ʻole.

4. Loaʻa i nā hopena pālua o nā nano a me nā micro powders, ʻoi aku ka haʻahaʻa o ka hana o ka ʻili, ʻaʻole hiki ke hui maikaʻi me nā pūʻulu hana ʻē aʻe, akā ʻaʻole maʻalahi hoʻi e agglomerate a hoʻomaʻamaʻa i ka hoʻopuehu pono.

5. Loaʻa ka hoʻopili maikaʻi, ka hopena pale nui a me ka hiki ke hoʻomālamalama i ka mālamalama.

6. ʻO ka pauka alumina tabular ʻaneʻane akaka, kala ʻole, a he palahalaha a paheʻe ka ʻili. He hexagons maʻamau nā kristal i hoʻoheheʻe maikaʻi ʻia.

7. Hiki ke hana i ka pauka alumina tabular i ka pauka polishing maikai loa.

1. ʻOihana uila: wili a me ka polishing o semiconductor monocrystalline silicon wafers, quartz quartz crystals, compound semiconductors (crystalline gallium, phosphating nano).

2. ʻOihana aniani: ka wili a me ka hana ʻana i ke aniani, ke aniani quartz, ka pale aniani kinescope, ke aniani aniani, ka wai aniani hōʻike (LCD) aniani substrate, a me ka aniani quartz.

3. ʻO kaʻoihana hoʻopili: nā mea hoʻopili kūikawā a me nā mea hoʻopihapiha no ka pīpī plasma.

4. Metal a me ceramic hana hana: precision ceramic mea, sintered ceramic maka mea, kiʻekiʻe-grade kiʻekiʻe-mehana uhi, etc.

Kou Ninau

Inā he mau nīnau kāu. E ʻoluʻolu e hoʻokaʻaʻike mai iā mākou.