Nā huahana

ʻO ka pauka ʻeleʻele ʻo Diamond Polishing Micro Powder

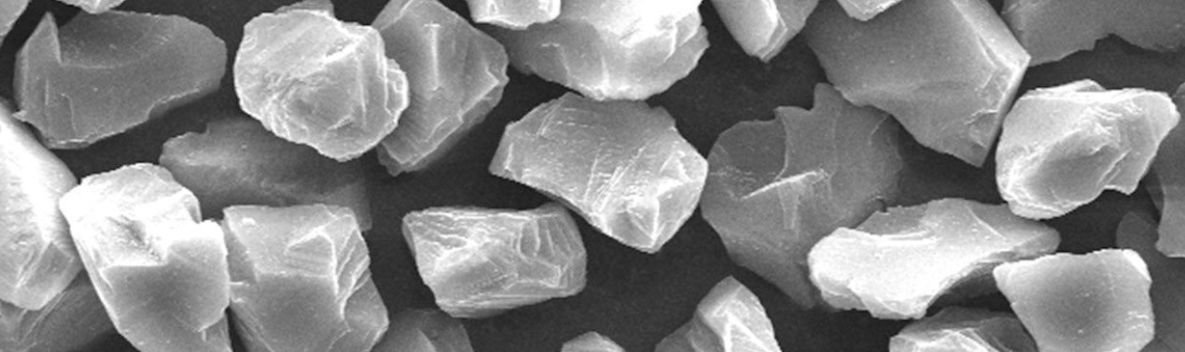

Monocrystalline Diamond Powder

Hoʻokumu ʻia ka Monocrystalline Diamond Powder mai ka daimana artificial single crystal abrasive grains e ke ʻano kaomi static, i ʻoki ʻia a hana ʻia me ka hoʻohana ʻana i kahi kaʻina hana kūikawā no nā mea paʻakikī. Paʻa kona mau ʻāpana i nā waiwai aniani hoʻokahi o ke daimana aniani hoʻokahi.

| Hōʻike | D50 (μm) | Hōʻike | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

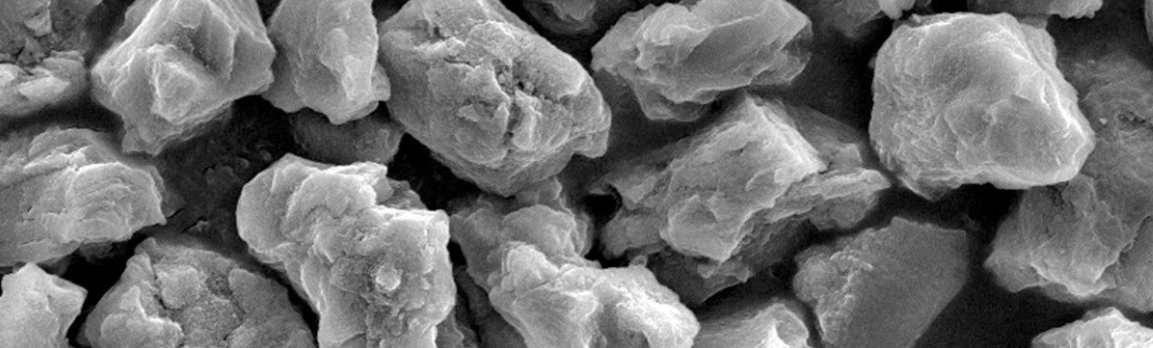

Polycrystalline Diamond Powder

ʻO ka pauka daimana polycrystalline he micron a me nā ʻāpana polycrystalline sub-micron i haku ʻia me nā hua daimana me ke anawaena o 5 ~ 10nm i hoʻopaʻa ʻia ma o nā paʻa unsaturated. He isotropic ka loko a ʻaʻohe mokulele ʻoki. Loaʻa ka paʻakikī kiʻekiʻe. Ma muli o kāna mau waiwai kū hoʻokahi, hoʻohana pinepine ia no ka wili a me ka polishing semiconductor mea, precision ceramics, etc.

Loaʻa nā nui o ka pauka micro daimana ma lalo nei:

Nā ʻano huahana

-Oversize wehe loa

- PSD haiki

- Hiki i ka maʻemaʻe o ka ʻili ke piʻi i ka pae ppm

-Ka hoʻopuehu maikaʻi

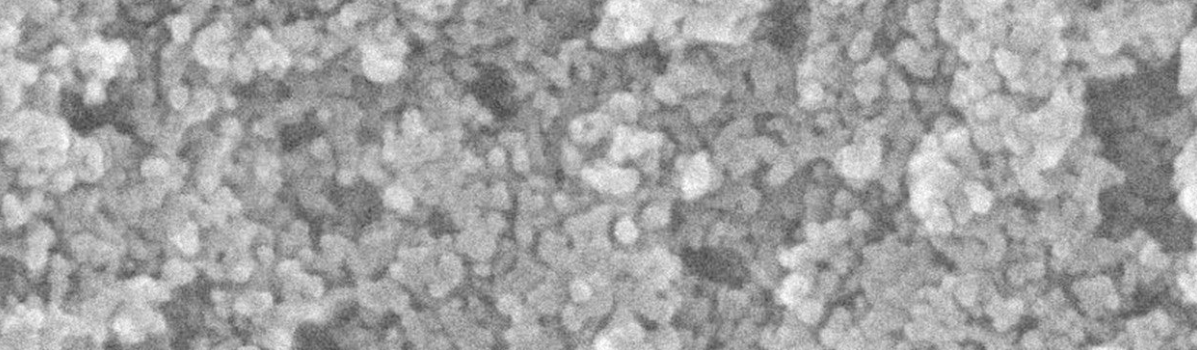

Nano Daimana Pauda

Hoʻokumu ʻia ka pauka daimana Nano me nā kristal liʻiliʻi ma lalo o 20 nanometer, ʻo ke kūlana detonative kūikawā e hoʻopuka i ka daimana sphere me ka pūʻulu hana waiwai ma ka ʻili, hoʻonui ʻia kona wahi kikoʻī e hoʻokahi kauoha o ka nui i hoʻohālikelike ʻia me ka daimana monocrystalline. ʻO kēia huahana ʻaʻole wale ka paʻakikī maikaʻi loa a me ka wili ʻana i nā hiʻohiʻona o ke daimana, akā loaʻa pū kekahi i nā hiʻohiʻona hou o nā mea nanofunctional.

| Nui | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Nā hiʻohiʻona

Hoʻohana ʻia ʻo Monocrystalline Diamond Powder

1. He kūpono no nā uwea daimana electroplated kiʻekiʻe, nā huila wili daimana electroplated, ʻokiʻoki kristal SiC, nā pahi, nā ʻili ʻili lahilahi, etc.

2. He kūpono no nā ʻāpana daimana hui, daimana polycrystalline a me nā mea hoʻopaʻa metala, nā huahana paʻa ceramic, nā huahana daimana electroplated, etc.

3. He kūpono no nā mea hana daimana electroplated, nā huila wili, a me nā mea ʻē aʻe i hoʻohana kūikawā ʻia no ka hana ʻana i nā mea paʻakikī a palupalu.

4. He kūpono no ka wili ʻana a me ka polishing o nā pōhaku makamae kiʻekiʻe, nā lens, nā mea hoʻohana metallographic, nā paneli LCD, nā aniani LCD, sapphire, nā ʻāpana quartz, nā substrates sapphire LED, nā aniani LCD, nā mea seramika, etc.

Hoʻohana ʻia ʻo Polycrystalline Diamond Powder

1.Thin a polishing o semiconductor wafers, e like me SiC wafer a me ka sapphire

2.Surface polishing o nā mea keramika like ʻole

3.Surface polishing o nā mea metala, e like me ke kila kila, ke alumini alumini a pēlā aku

Nano Diamond Powder Noi

1. ʻO ka poli maikaʻi loa. Hiki i ka ʻeleʻele o nā mea hana i hoʻomaʻamaʻa ʻia ke hiki i ka pae angstrom me ka ʻole o nā ʻōpala, hiki iā ia ke hoʻokō i nā noi polishing ikaika loa.

2. Nano daimana hiki ke hoʻohana 'ia e like me lubricating aila additives. E hoʻololi ʻia ka friction sliding i rolling friction, hiki ke hōʻemi i ka friction coefficient a hoʻomaikaʻi nui i ka hana friction a hoʻolōʻihi i ke ola lawelawe.

3. ʻO ka hoʻopili ʻana a me ka pulupulu ʻana ma luna o ka ʻili o nā mea hana like ʻole, hoʻonui i ka pale ʻana i ka ʻaʻahu, ke kū ʻana i ka corrosion, ka paʻakikī a me ka paʻakikī o ka ʻili o ka mea hana.

4. E like me nā mea hoʻohui a me nā plastics, hiki i ke daimana nano ke hoʻoikaika nui i kona pale ʻana i ka ʻaʻahu, ke kūpaʻa puncture, ka waiwai tensile a me ka hoʻolohi ʻana i ke kaʻina hana ʻelemakule.

5. High maemae nano daimana e ole kumu biological rejection, ia manawa hiki ke hoʻohana nui 'ia i loko o lapaʻau, biological a me ka hoʻomaʻemaʻe kahua ma muli o kona nui kiko'ī ili wahi, ikaika adsorption hiki.

Kou Ninau

Inā he mau nīnau kāu. E ʻoluʻolu e hoʻokaʻaʻike mai iā mākou.